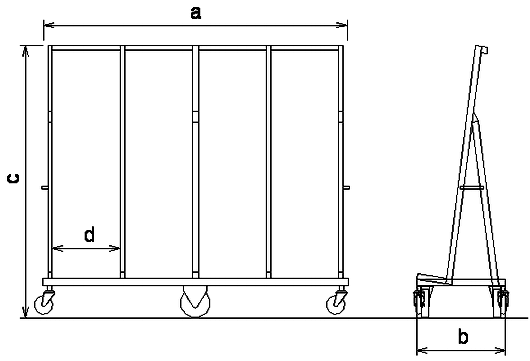

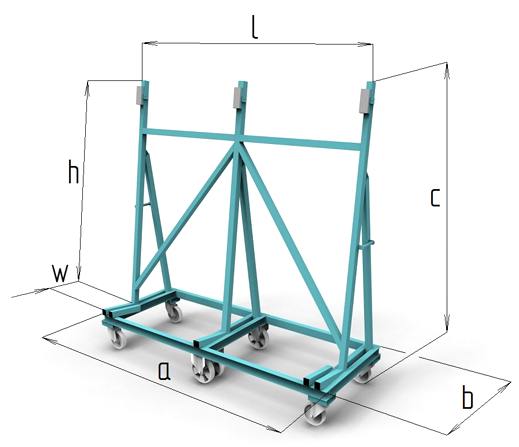

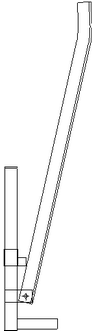

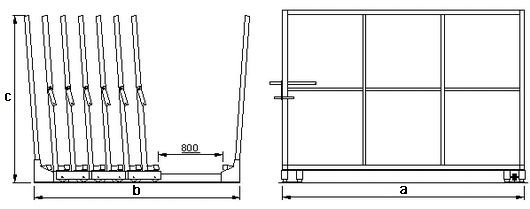

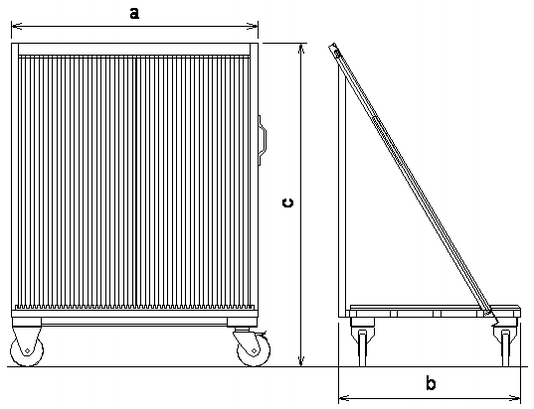

Model RJTM

It is used for storing the window sheets. The vertical surface of leaning is seen with a rubber band of 3mm. The lower placing part on which the window is put, there is a 15mm padding.

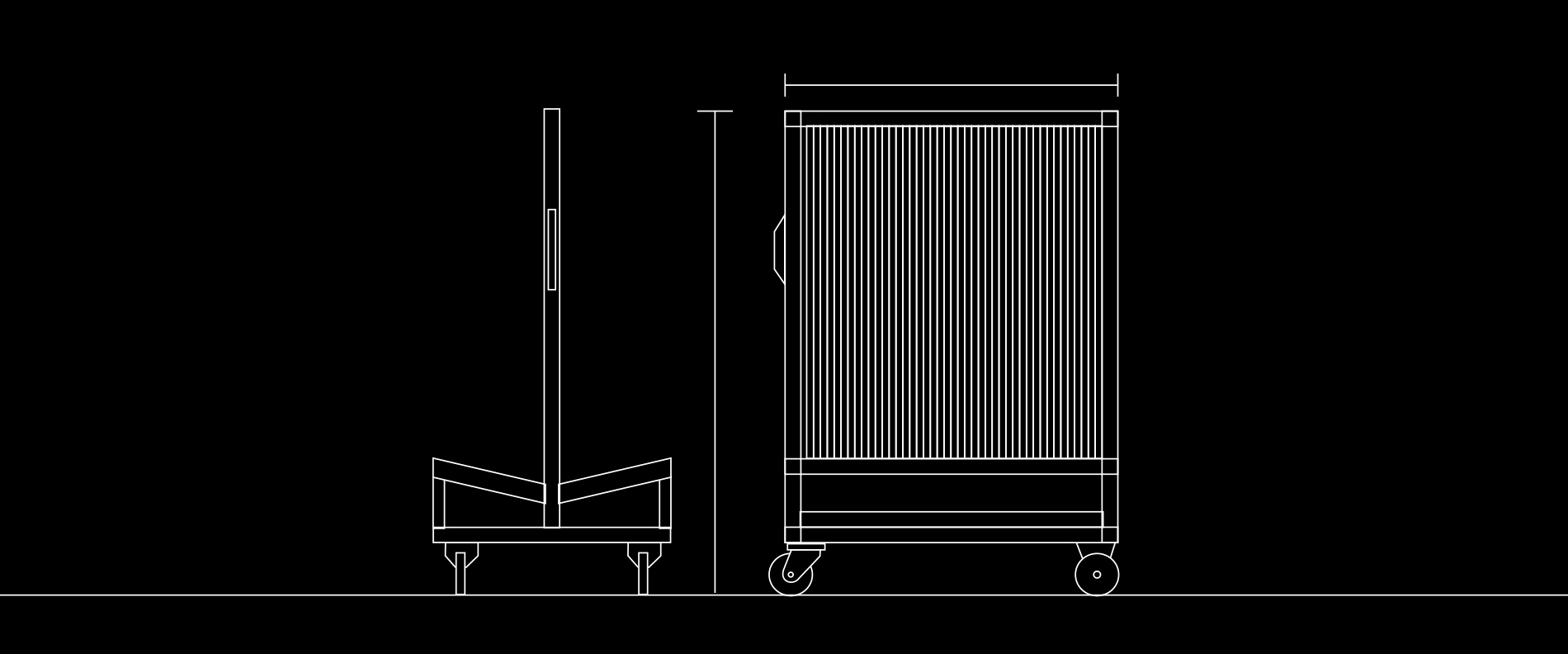

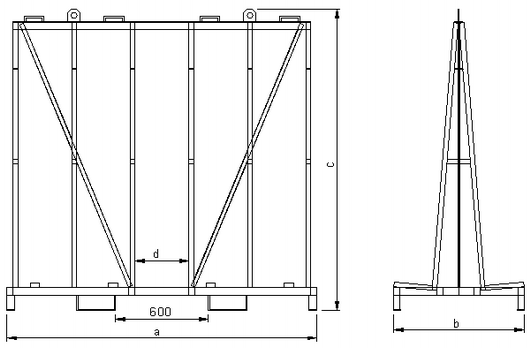

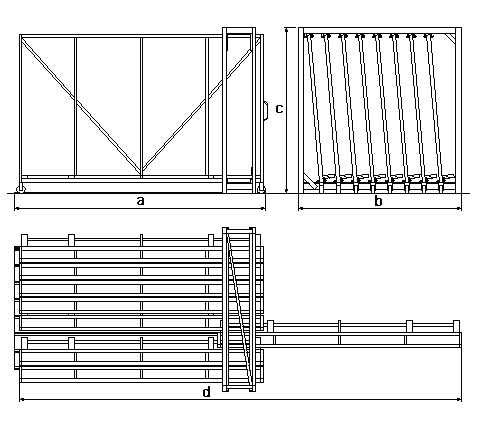

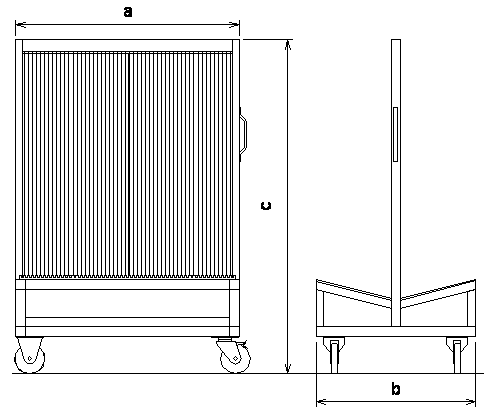

Model RBM

It is used for storing window boxes. The vertical bars from the metallic structure of the placing surface are equipped 4 rubber pads which the window is placed on, which confers the dismantling of the box with more ease.

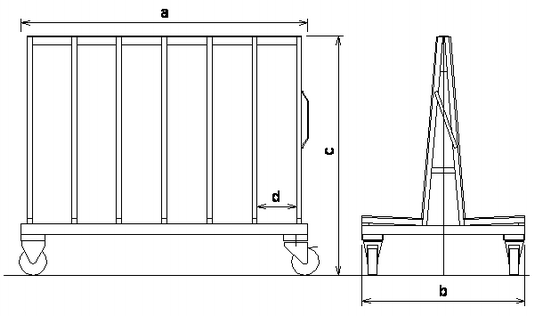

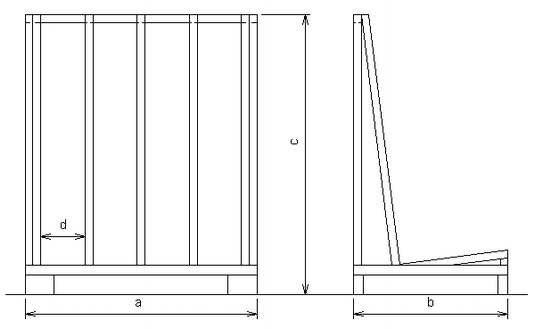

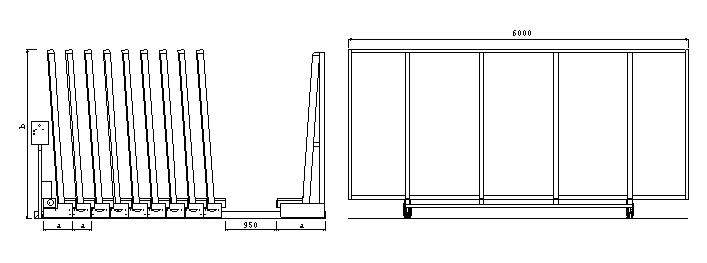

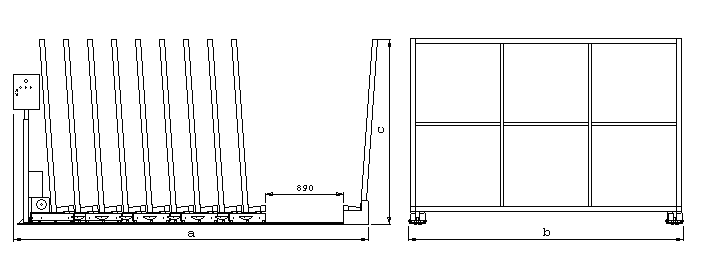

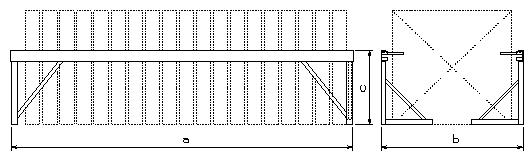

Construction: The steel frame cannot be dismantled and it is welded from the rectangular pipe with finished surface in RAL nuances. The mobile frames are placed along with two rails of 20mm in height which facilitates the access in the work space. The movement of the frames is made with the help of an action with the electric motor and revving dimmer which allows a large amount of adjustments in accordance with the load transported by the frame train. This construction assures the maximum comfort and safety of the operator. The operation is done automatically and in the mean time, the operator can do other activities which helps with productivity. The whole system can be equipped initially with manual operation with handles, which can be replaced with the engine system.

How to use for the electrical operation type:

Upon stepping on the pedal in the selected position and pressing the activation button, the frames are automatically moved to the end positions, creating a gap in front of the selected position. During the process, the operator can carry out other preparatory tasks. The drive is stopped automatically if the operator enters the manipulation area while it is moving. (preventing undesired accidents).

How to use for the manual operation type:

The process is identical with the previous explanation with the only difference being that the operation is done manually, with the help of a handle type mechanism. The length of the lever can be adjusted so that the motor moment can overcome the resistance generated by the effort on the frame train assemble. In this case, the operator is participating in both selecting and generating workspace.